Safety

Concrete Alberta considers safety as a major concern for every person involved in the ready mixed concrete industry. It is vital that members of this association make safety a top priority at all times. By working together as a team, accidents can be substantially reduced.Although Concrete Alberta does its best to ensure that any advice, recommendations or information it may give is accurate, no liability or responsibility of any kind (including liability of negligence) is accepted in this respect by Concrete Alberta or the Alberta Ready Mixed Concrete Association or any of its affiliated members, servants or agents.

The objective and scope of this Member's Only Safety Page is to share items of common interest and to learn from one anothers' experiences. By keeping everyone informed in a timely manner of any serious safety incidents, we can hopefully avoid their recurrence in any of our businesses.

SERIOUS EVENT REVIEWS (SER's) have been submitted, with permission, by members of our Safety Committee. Privacy has been protected by posting generic versions of actual incidents experienced by our member organizations. Though further inquiry into a particular incident presents challenges with respect to preservation of privacy, submissions to Paul Masson will be accepted and will receive replies subject to the member company's willingness to provide the information.

Worker Falls Under Icy Conditions

At a remote hydro electrical power construction site workers were preparing for 2 days of high volume concrete pours. Two additional workers were brought into the camp from other locations for the duration of the pours. The batch plant is a portable plant with a narrow access route for mixers to back under and is lined by lock blocks, one row high, on the driver’s side.

A safety meeting was held at 0700 hours on January 13th where icy conditions and general site conditions were discussed. A daily hazard assessment was completed at that time.

Later that day a worker backed a mixer truck under the plant to be batched and before leaving from under the plant the worker was asked to check the slump / wetness of the concrete. When the worker was descending the ladder and stepping from the mixer’s ladder onto an ice covered lock block, from approximately 1.0 meter (39 in.) high the worker slipped and was not able to hold on due to icy ladder side rails. The worker struck the edge of the lock block with the left side of the body.READ MORE

Mixer Truck Roll-over

Failure to Identify Hazard

Failed Lifting Device

A Ready Mix truck had a failed drum gear box with 3-4m3 of hardened concrete in the drum. A contractor was brought in to jackhammer the concrete but could not complete the job before having to report to a previously scheduled job. The truck was brought into the shop for repair and disassembly of the drum drive began. In order to remove all connecting hardware from the drum drive, the drum needed to be rotated approximately 90 degrees. The worker planned to use a sling and a hook device designed for lifting drums. The sling and hook device was attached on one end to an overhead crane for lifting and on the other end in the open drum hatch. The worker verified with the lead hand on shift that this would be the correct method to move forward. While rotating the drum, as the hatch came to approximately the 12 o'clock position, the hook device failed, causing the drum to roll back. READ MORE

Failure to Identify Hazard

A fatality occurred during the unloading of fly ash at a ready-mix plant site. While a bulk truck driver was

unloading fly ash into the silo, the filter from the customer silo was blown15 meters into the air, flew over

an adjacent silo, and fell down striking and killing the driver (Read More).

Click Here for a Silo Over-Pressurization Prevention Guide

Heavy Equipment Incidents & Near Misses

Recently there has been a rash of damage or near miss events between light vehicles and heavy equipment.

When heavy equipment contacts light vehicles, the potential for serious or major injuries is very high and,

damage costs for these types of incidents are also very high. Please ensure operators and workers understand

the importance of yielding right of way to heavy equipment and that operators are vigilant in watching for light

vehicles and other equipment and exercise caution when they are near (Read More).

Archived SER's:

Worker Falls Due To Unsafe Site Access (2015)

Improper Safe Work Practice / PPE / Communication (2015)

Alberta Health & Safety eNews Letter

Stay up to date with the latest news from OH&S on topics related to legislation and local safety initiatives. Track monthly and annual safety stats and see how your business stacks up against industry averages. Attached is the December 2016 edition. If you like this publication, please go online and subscribe - it's free!

Alberta WBC General Statistics

Here's another opportunity to "look at yourself in the mirror" and to ask the following questions:

"How does my company's safety record compare to current reported WCB stats?"

"Do I have provisions in place that demonstrate my company's commitment to continuous improvement?"

"Given our recent safety stats, should I anticipate a visit from OH&S anytime soon?"

Again, track monthly and annual safety stats and see how your business stacks up against industry averages by going to:

WCB General Statistics Reports and look under the following sub headings:

Construction and Construction Trade Services and look under Mobile Equipment and then also look at

Construction and Construction Trade Services and look under Mobile Equipment and then also look at

Manufacturing, Processing and Packaging and look under Transit Mix Operations

Manufacturing, Processing and Packaging and look under Transit Mix Operations

WHMIS 2015

WHMIS is in transition as it goes through a merger with the Globally Harmonized System over the next 3 years. The WHMIS we’ve known to date is taking on a new look with slightly different symbols and revised labels and safety data sheets (SDS). The new system in Canada will be referred to as WHMIS 2015.

Some product suppliers are already well down the road of transition to WHMIS 2015 and our members are seeing that change reflected in the labeling and SDS of the products they receive every day. This signals the need for our member companies to start to develop their WHMIS 2015 Training Toolbox Sessions. Alberta Safety Construction Association has a WHMIS 2015 video update posted on You Tube that gives us a look at a transition process at a worksite.

There are also a number of firms that have tried to capitalize on this transition training opportunity who may not be able to provide the training that your firm needs to be compliant. Please have a look at the following link at Work Safe Alberta for more information on what you will need to do to fulfill WHMIS Training requirements through the transition process to WHMIS 2015. http://work.alberta.ca/documents/WHS-PUB-AL035.pdf

As an employer you are obligated to provide training of your employees through the transition process as your firm receives products with the new WHMIS 2015 labels and SDS.

Concrete Alberta Safety Committee

Safety Data Sheets & WHMIS Label Samples:

The following is an example of an Alberta Concrete Producer SDS and WHMIS label for Ready-Mixed Concrete.

Another example may be found at Lehigh Hanson's site

A generic example of a WHMIS label which should appear somewhere on every concrete load delivery ticket - usually on the back might look something like this:

Some Additional Supplier Website Links

The following are links to websites of a number of Concrete Materials Suppliers such as cement, chemical and mineral admixture suppliers. You are mandated by law to have a copy of the most current SDS for each controlled substance on your premises.

Please consult with your supplier contacts and websites annually for any updates.

Cement

Cement Association of Canada

Cement Suppliers

Ash Grove Cement Company

CRH Canada

Lafarge Canada Inc.

Lehigh Hanson Canada

Supplementary Cementing Materials

ASHCOR Technologies Ltd. (Fly Ash)

BASF Admixtures Inc. (Silica Fume)

Cementec Industries (Silica Fume and HardCem)

ENX Inc. (Fly Ash and Blends)

JR & W Consultants, Inc. (Silica Fume)

Lafarge Canada Inc. (Fly Ash, Silca Fume, Slag Blends)

Lehigh Hanson Canada (Fly Ash and Blends)

Chemical Admixtures

BASF Admixtures

Euclid Chemical

GRACE Canada Inc.

Kryton International Inc.

Sika Canada Inc.

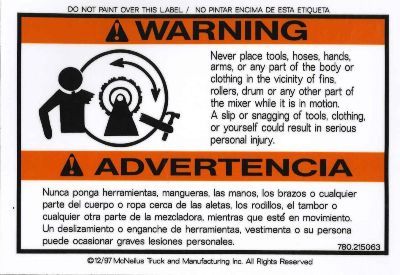

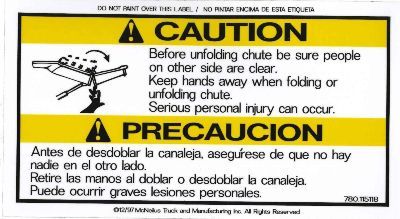

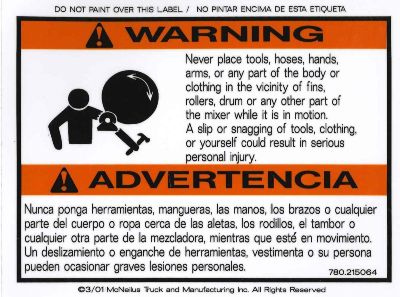

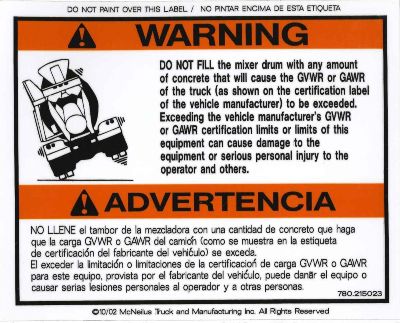

REINFORCE YOUR DRIVERS' SAFETY AWARENESS

Vehicle Stickers

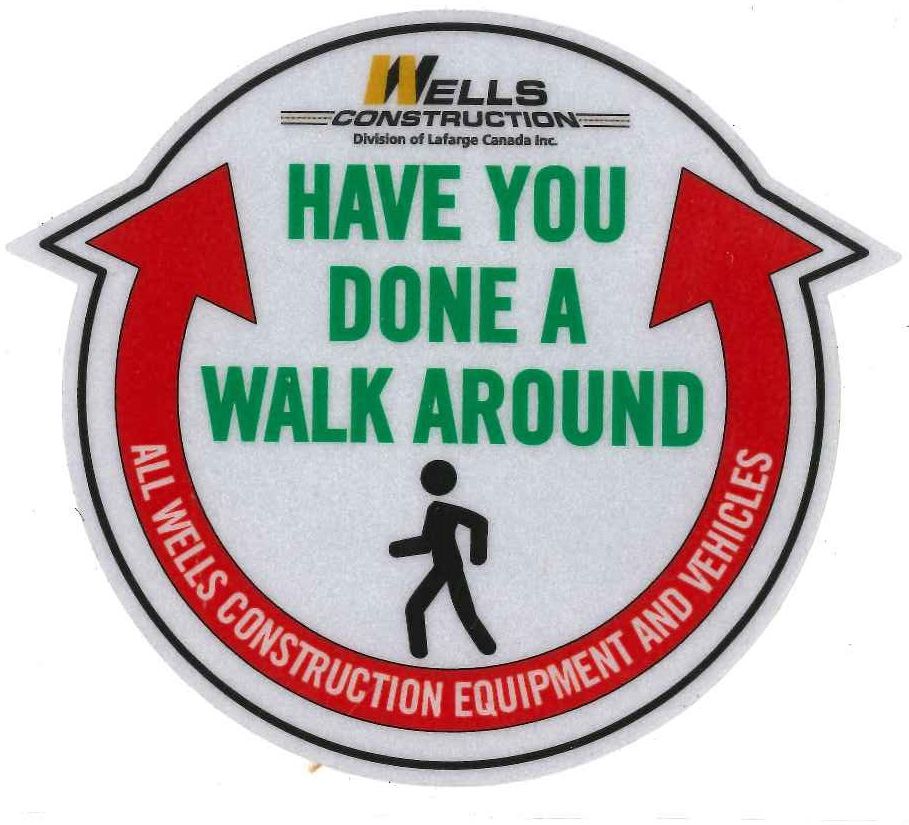

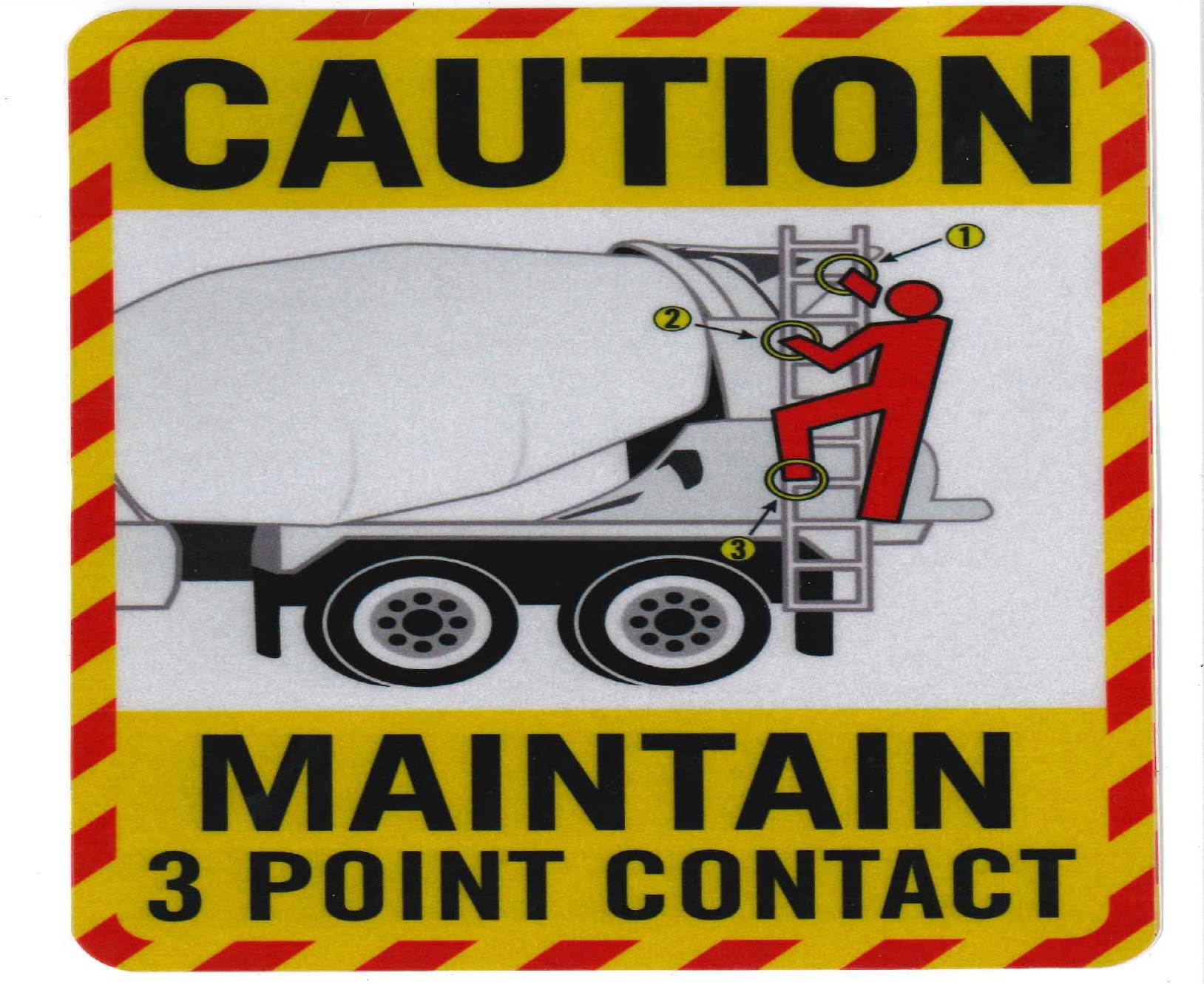

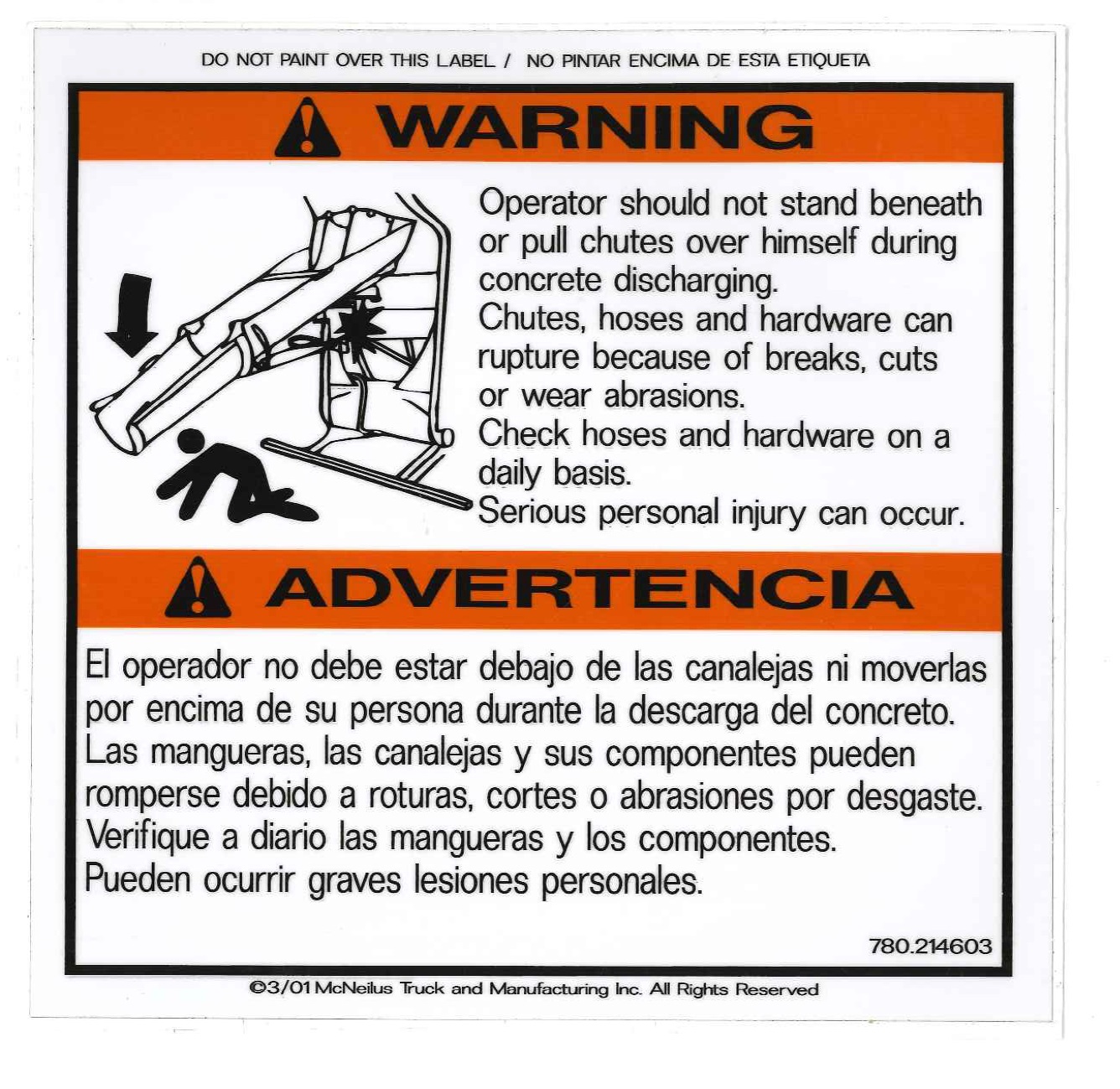

Some member producers have improved their drivers' awareness by placing a series of sticker on their ready-mix trucks to remind drivers of the hazards they are facing. These posts include reminders about pinch points, line of fire risks, overloading and the need to always do a walk around of the vehicle before departing. The stickers are intended to remind drivers to be more mindful about safety when working around their equipment as well as those of others around them in the field. This administrative control can be used in combination with other control measures to increase awareness and to reduce the number of injuries sustained during the course of an average work day. To have these stickers printed with your logo for your fleet, contact Vimark Solutions at http://www.vimark.ca/

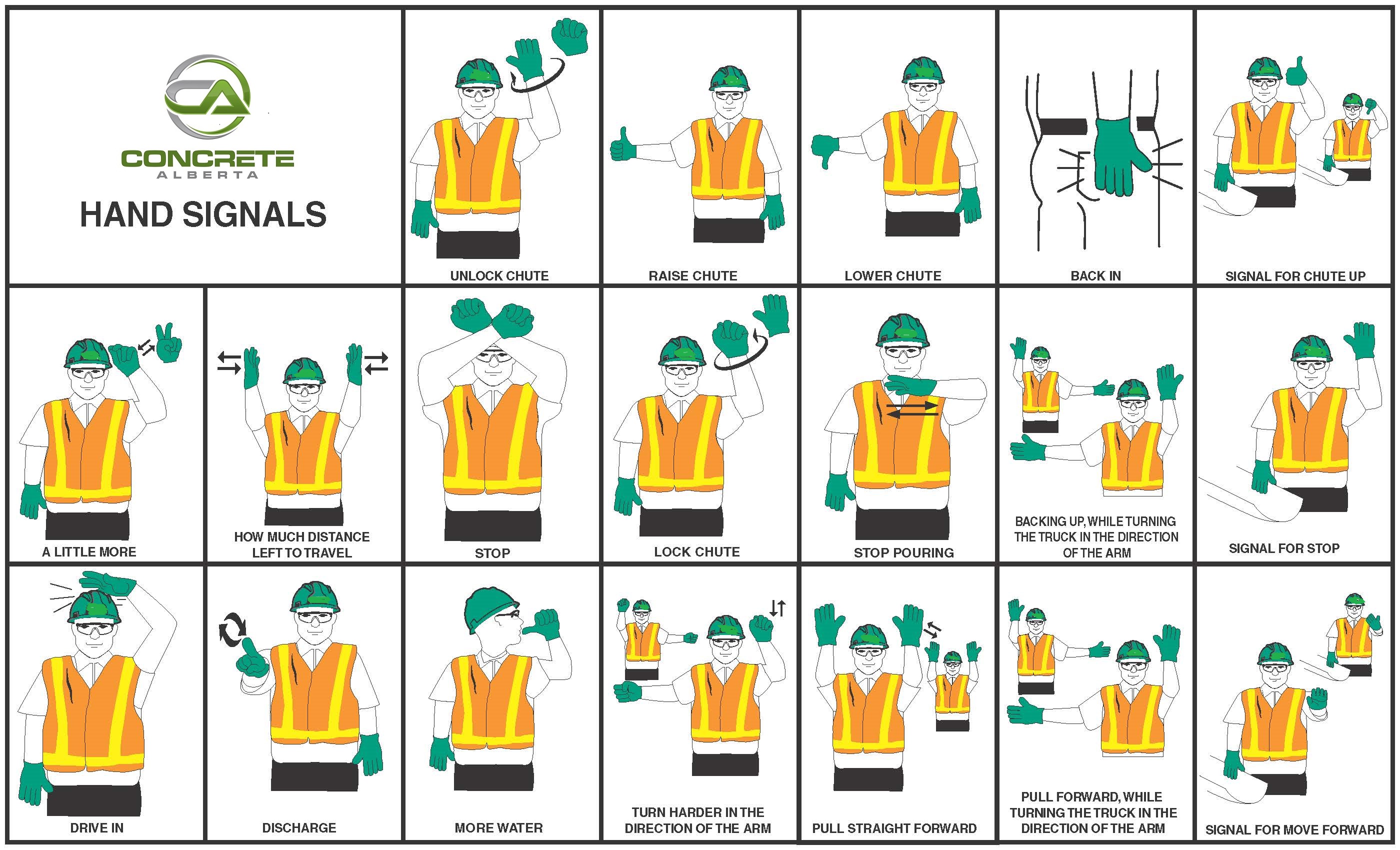

Hand Signals Chart / Poster

Every driver should be well acquainted with hand signals that are commonly used on site to communicate over typical industrial noise levels and in areas where hearing protection is mandatory.